Application Cases

Application of Vigor Inclinometers on Water Dam for Attitude and Structure Monitoring

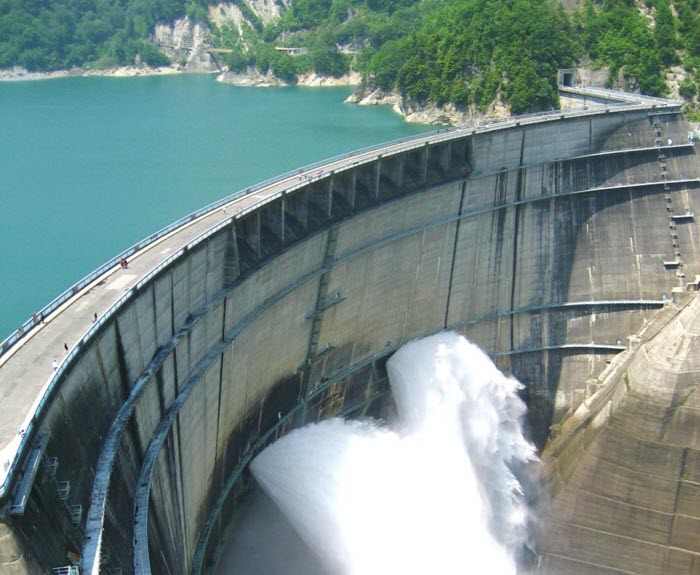

Dams are generally used to intercept rivers and rivers to regulate flow, and have functions such as flood control, irrigation, hydropower generation, and improved shipping. Many safety factors, such as soil permeability, frequency of earthquake occurrence, landslides, landslides and other natural disasters, will affect the safety of dams, cause dam collapse accidents, and bring life and economic losses to nearby and downstream residents.

Application of Inclinometer Sensors in Dam Attitude and Structural Deformation Monitoring

"On May 10th, 2018, 48 people were killed as a result of a dam burst on a Kenyan farm. Half of the people killed were children. When the dam burst on May 10th following heavy rain, 5000 people were left homeless and three villages washed away." Quotation from rushhourdaily.com.

Dam safety monitoring has received more and more attention from government. Since deformation monitoring can directly reflect the dam's operational behavior, many abnormal dam behaviors are initially reflected by the abnormality of deformation monitoring values. Therefore, the deformation monitoring project is listed as the preferred monitoring project for dam safety monitoring. Via monitoring the dam body tilt and deformation, the deformation law of the dam body and foundation can be understood intuitively and quickly.

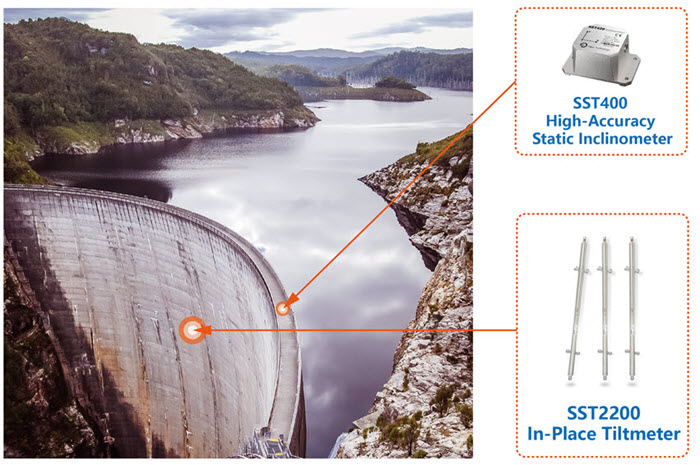

The dam monitoring system includes inclinometer sensors and tilt meter to monitor the dam deformation parameters in real time. The high-precision inclinometer sensor reflects the subtle angular changes of the dam. The tilt meter can monitor the dam body safety related data such as surface displacement and internal displacement of the dam. These monitoring data are transmitted to the dam operation control center. The dam maintenance personnel can make dam safety assessment based on the monitoring data, and truly achieve early warning. All-round contingency measures for dam collapse shall be carried out to ensure the safety of dams and the safety of residents' lives and property.

How Does the Vigor Inclinometer Sensor Overcome the Dam Deformation Monitoring Problem?

Common inclinometer sensors on the market have problems such as zero drift and temperature drift, which ultimately lead to serious measurement and detection errors. Vigor technology products use Vigor's proprietary automatic testing technology to test, correct and compensate for temperature drift characteristics, nonlinearity, and spatial position of horizontal axis error sensitive axes, effectively serving zero drift and temperature drift.

The Vigor SST400 digital inclinometer is densely arranged at each monitoring point of the dam body, and has a biaxial attitude measurement accuracy of up to ±5". At the same time, each SST400 undergoes strict compensation and maintains stable measuring performance under the conditions of large temperature difference between day and night in the field environment. For the dam vibration mode, the SST400 attitude calculation and filtering algorithm are optimized to ensure the accuracy and stability of attitude measurement. The inclinometer sensor is connected through the LORA (optional NB-IOT) communication mode, and the data is uploaded to the cloud wirelessly. Very low power consumption, internal lithium battery combined with solar power supply, can guarantee continuous working time of more than 5 years, and it does not need the characteristics of field wiring, which brings great flexibility and convenience for on-site measuring point selection and construction layout.

Vigor SST2200 Slope Inclinometer has the same quality control as the SST400 in design and production. It has a resolution of 0.002° and a full temperature range accuracy of ±0.01°. It supports the slope measurement ability of up to 100m depth, interconnected by a single CAN bus. The measured oblique data is sent to the ground data collection device and uploaded to the cloud wirelessly for use by the monitoring terminal.

Categories

Applications

- Inclinometer Sensors for Dam Health Monitoring And Dam Deformation Monitoring

- TMS Intelligent Transmission Tower Safety Monitoring System Solution

- Applications of Vigor Sensors in Wind Turbine Installation and Health Monitoring

- Communication or Telecom Tower Safety Monitoring Solution with Inclinometers and Sensors

- Application of Inclination Sensor on Telescopic Handler for Tilt Monitoring

Contact Us

Contact: Vigor Technology

Phone: +86 18017387742

Tel: +86 021-58404921

E-mail: sales@vigordigital.com

Add: Block H1, No. 161, Lane 3188, Xiupu Road, Pudong New District, Shanghai